In the competitive landscape of appliance manufacturing, staying agile and innovative is paramount. As industry leaders grapple with increasing demands and evolving market dynamics, the concept of outsourcing certain processes, particularly appliance injection molding projects, has gained traction. But what exactly are the strategic advantages of this move? Let’s break it down.

The Economic Benefits of Outsourcing: Cost-Effective Appliance Injection Molding

When we talk about outsourcing, especially in the realm of appliance injection molding, the immediate thought often veers towards cost savings. And while it’s true that outsourcing can significantly reduce expenses, its value extends far beyond the balance sheet.

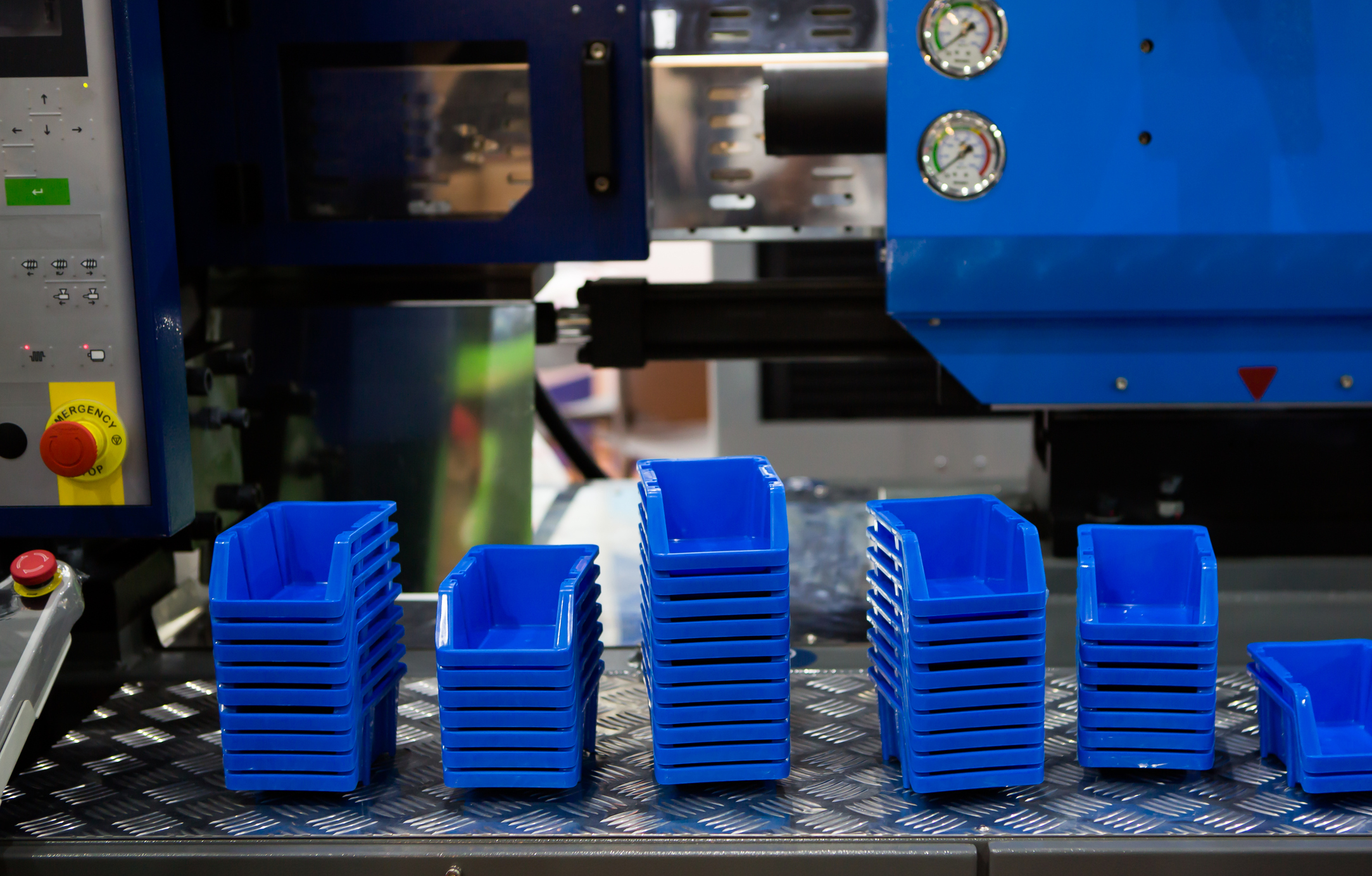

At its core, outsourcing is a strategic maneuver. By sidestepping the hefty capital expenditure of establishing in-house facilities, training specialized staff, and the ongoing costs of equipment maintenance, companies can channel their resources more effectively. Partnering with seasoned providers, like Hansen Plastics, allows businesses to tap into a reservoir of established infrastructure and deep-seated expertise. This not only ensures a tangible return on investment but also elevates the quality of the end product.

But the economic advantages don’t stop at cost-effectiveness. In the fast-paced world of appliance manufacturing, agility is the name of the game. The ability to rapidly prototype, iterate designs, and refine products is paramount. Outsourcing supercharges this process. With access to specialized tools and expertise, companies can accelerate their prototyping, ensuring they’re not just first to market, but that their products are perfectly attuned to market demands. This agility, combined with the cost savings, positions businesses to not just compete but to consistently outpace their competition.

In essence, the economic benefits of outsourcing appliance injection molding projects are twofold: it’s a masterstroke for financial efficiency and a catalyst for competitive agility.

Harnessing Expertise and Innovation: High-Quality Appliance Injection Mold Design

In the intricate world of appliance injection molding, the difference between a good product and a great one often boils down to the nuances of design and technique. This is where outsourcing shines as a beacon for companies aiming for excellence.

By choosing to outsource, companies unlock a treasure trove of specialized talent and cutting-edge techniques. Take, for instance, the realm of injection mold design. It’s not just about creating a mold; it’s about crafting a masterpiece that ensures precision, durability, and high performance. Firms like Hansen Plastics, with their laser-focused dedication to this craft, have elevated mold design to an art form. Their deep-seated expertise ensures that every mold is not just functional but optimized for excellence.

But the expertise doesn’t stop at design. Delving deeper into the molding process, we encounter techniques like overmolding. This intricate process, which involves molding material over an already molded base, is a game-changer in enhancing both the durability and aesthetics of appliance parts. It’s a delicate dance of materials, temperatures, and timings. And while it’s complex, when executed by experts, the results are nothing short of spectacular. Outsourcing provides companies with the assurance that such advanced techniques are handled with the finesse and expertise they demand, leading to products that stand out in both form and function.

Ensuring Appliance Injection Molding Quality Control

In today’s dynamic manufacturing landscape, two imperatives stand out: an unwavering commitment to quality and a resolute focus on sustainability. For companies in the appliance manufacturing sector, these aren’t just buzzwords; they’re foundational principles that guide every decision.

Quality, as we know, is the bedrock of manufacturing. It’s the promise companies make to their customers, ensuring that every product that rolls off the assembly line is impeccable. But achieving consistent quality isn’t a walk in the park. It demands rigorous protocols, meticulous oversight, and a culture of excellence. This is where the value of outsourcing becomes evident. By partnering with specialized firms, companies gain access to established quality control systems honed over years of experience. Firms like Hansen Plastics, for instance, bring to the table a legacy of quality assurance, ensuring that every product not only meets but exceeds both industry benchmarks and client expectations. The result? Products that resonate with reliability, durability, and excellence.

But in an era where the environmental impact of manufacturing is under the microscope, quality alone isn’t enough. The clarion call for sustainability is louder than ever, pushing manufacturers to rethink their processes, materials, and waste management strategies. Here again, outsourcing emerges as a strategic ally. Many specialized molding partners have been at the forefront of sustainable manufacturing, championing green initiatives long before they became mainstream. Whether it’s the adoption of eco-friendly materials, innovative waste reduction techniques, or energy-efficient processes, these firms offer a roadmap to sustainability. By aligning with such partners, companies can not only enhance their environmental stewardship but also position themselves as leaders in sustainable appliance manufacturing.

Seamless Integration and Production Optimization

In the intricate dance of appliance manufacturing, every step, every component, and every process must synchronize perfectly. It’s a world where precision meets pace, and any misstep can ripple through the production line, causing delays, inefficiencies, or quality issues. This is especially true when introducing outsourced components into established assembly lines. The challenge? Ensuring that these new components integrate seamlessly, maintaining the rhythm and flow of production.

But here’s the silver lining: experienced outsourcing partners, like Hansen Plastics, have mastered this dance. With years of experience and a deep understanding of both the art and science of injection molding, they bring to the table solutions that ensure smooth integration. Whether it’s adapting components to fit existing machinery, tweaking designs for better assembly line compatibility, or offering insights to streamline workflows, these experts ensure that production continues uninterrupted, maintaining both pace and quality.

Yet, the value of outsourcing extends beyond mere integration. It’s about elevating the entire production process. Specialized firms, with their laser focus on injection molding, are in a constant state of evolution. They’re always on the lookout for ways to refine processes, adopt cutting-edge technologies, and enhance efficiency. This commitment to continuous improvement means that when you outsource, you’re not just getting a component; you’re getting an upgraded version of your production process. It’s like swapping out a regular engine for a turbocharged one!

But, as with all strategic decisions, the key to successful outsourcing lies in choosing the right partner. It’s about aligning with a firm that shares your commitment to excellence, understands your unique challenges, and brings to the table both expertise and innovation. Hansen Plastics, with its legacy of quality, dedication to innovation, and a team of seasoned professionals, embodies these qualities. For companies looking to harness the full potential of outsourcing in appliance injection molding, Hansen Plastics isn’t just a provider; it’s a partner in progress.