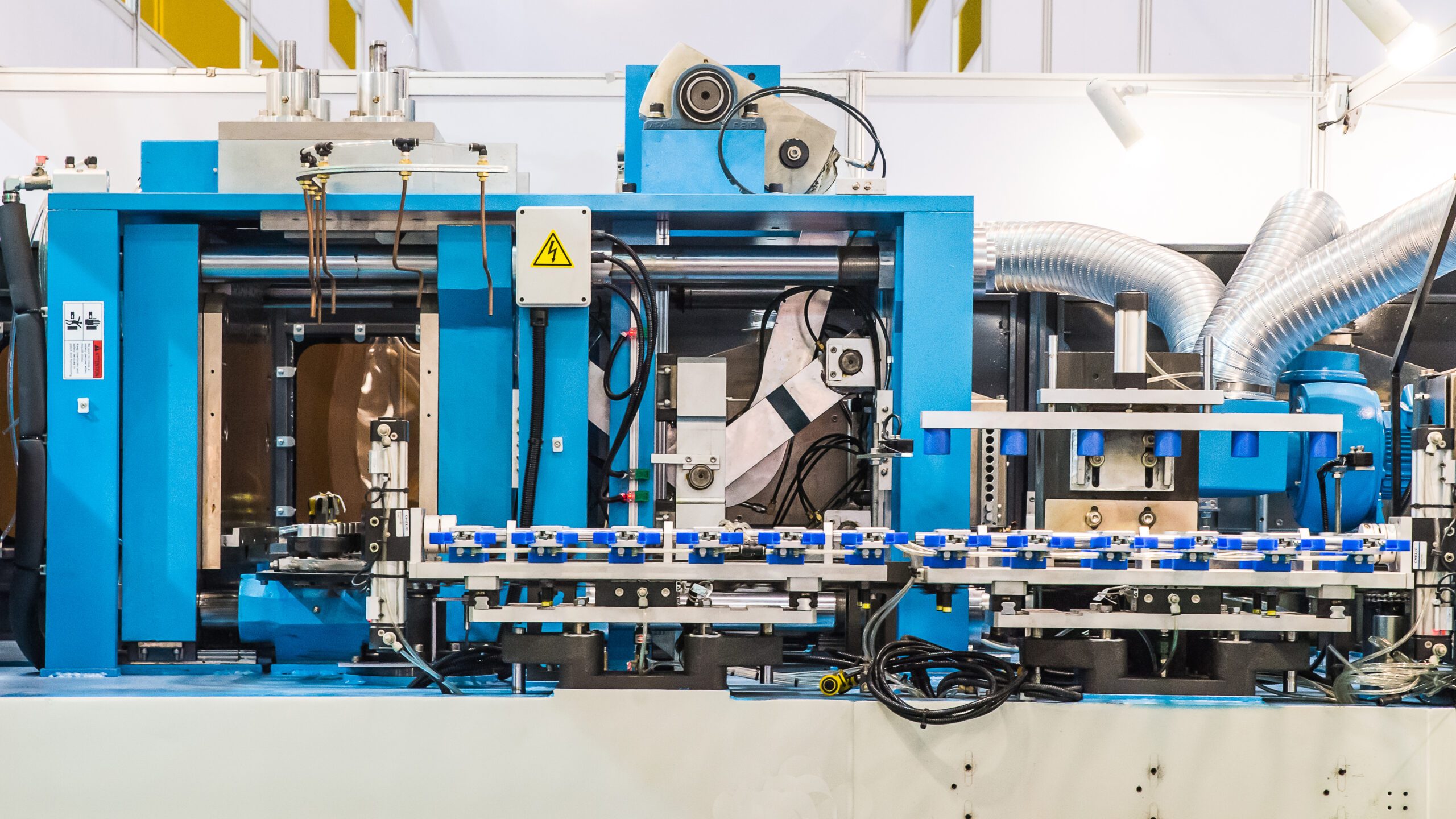

Achieving perfection is essential when it comes to creating household appliances. That’s where plastic injection molding comes in. It’s like a cool technique that helps make stuff with plastic. One awesome thing about it is the decoupled molding. It’s like a new way to make things even better and faster. But you know what’s important? Making sure everything is top-notch quality. That means no mistakes or flaws. Let’s talk about why this is so crucial, especially when it comes to making home appliances.

Role of Decoupled Molding in the Production of Appliances

Decoupled molding is a super cool technique that makes plastic injection molding even better. It splits the whole molding process into different parts, which helps control things like temperature, pressure, and how long each step takes. This careful control makes sure that every appliance comes out just right, without any mistakes. It’s like having a recipe where you measure everything exactly to make the perfect cake. With decoupled molding, manufacturers can make sure that each appliance they produce is top-notch quality, which means happier customers in the end.

Moreover, decoupled molding allows manufacturers to fine-tune each stage of the process independently, optimizing efficiency and reducing waste. By isolating variables like temperature and pressure, it minimizes the risk of defects and ensures consistent quality across production runs. This precision ensures that appliances not only meet but exceed industry standards, setting a new benchmark for excellence. Ultimately, decoupled molding revolutionizes appliance production, paving the way for innovation and customer satisfaction.

The Significance of Quality Control

Quality control is like the superhero of decoupled molding for home appliances. It’s super important because it’s what makes sure everything goes smoothly. You see, even tiny changes in how we make things can make a big difference in how good they turn out. If we’re not careful, those changes can lead to appliances that don’t work right. Think about it: a fridge with a weak structure or a dishwasher with leaks because the parts weren’t made perfectly. That wouldn’t be good at all! Not only does it make the brand look bad, but it could also be dangerous for people using those appliances. Plus, it can cost a lot of money for manufacturers if they have to fix or replace faulty products. That’s why quality control is so crucial—it helps prevent all these problems and ensures that every appliance manufacturing through plastic injection molding comes out as top-notch quality.

Key Steps in Implementing Quality Control

Implementing quality control involves a few key steps to ensure everything goes smoothly. First, we need to figure out what things are most important to check in our products. Then, we set standards for how good these things need to be. Finally, we make sure everyone knows how to keep an eye on quality during the plastic injection molding process. By following these steps, we can guarantee that every product meets the high standards we aim for. Following are some key steps:

Identification of Critical Quality Parameters:

Manufacturers need to figure out what things are really important to check in their products. This includes stuff like how big something is, what it’s made of, and how smooth it feels. By paying attention to these details, they can make sure their products meet the standards they want.

Setting Quality Standards:

To make sure every appliance is good, manufacturers set rules for how good they need to be. These rules are like targets that the appliances have to hit. By having these rules in place, manufacturers can keep things consistent and reliable. It’s like having a goal to aim for, so everyone knows what’s expected.

Training Staff:

Making sure workers know what they’re doing is important for quality control. They need to learn about how decoupled molding works and how to spot any problems that might come up. This way, they can make sure everything goes smoothly and the products turn out great. Training programs help them understand all of this stuff so they can do their jobs well.

Benefits of Effective Quality Control

Effective quality control brings many benefits to the table, especially in plastic injection molding. It’s like having a secret ingredient that makes everything better. By keeping a close eye on how things are made, manufacturers can ensure that their products are top-notch. This not only boosts customer satisfaction but also strengthens the brand’s reputation in the competitive market. Plus, it saves time and money by reducing the need for fixes or replacements. Effective quality control yields numerous benefits:

- Improved Product Reliability and Longevity:

When appliances are made using decoupled molding and careful quality control, they last longer and work better. This means they’re less likely to break too soon, which is really good news for everyone. With these methods, manufacturers can make sure their products are reliable and will keep working well for a long time.

- Enhanced Customer Satisfaction:

When customers get appliances that are always top-notch, they’re super happy! This makes them trust the brand more and want to buy from them again. Plus, happy customers often tell their friends about the great stuff they bought, which brings in even more sales. So, by making sure products are really good, manufacturers can keep customers happy and their brand growing.

Conclusion:

In the world of making appliances, being excellent is super important. By using decoupled molding and making sure everything is top-notch quality, manufacturers can make amazing products. This not only meets what customers expect but goes above and beyond. When companies invest in quality control, it’s like they’re making a promise to their customers: that they’ll get the best stuff every time. This builds trust and makes customers want to stick with that brand. So, when we combine decoupled molding with quality control in plastic injection molding, it’s like a winning recipe for success in the appliance world. It’s all about making sure every product is great, every customer is happy, and every brand keeps growing. With this approach, manufacturers can stand out and thrive in the competitive market, setting new standards for excellence in home appliances.