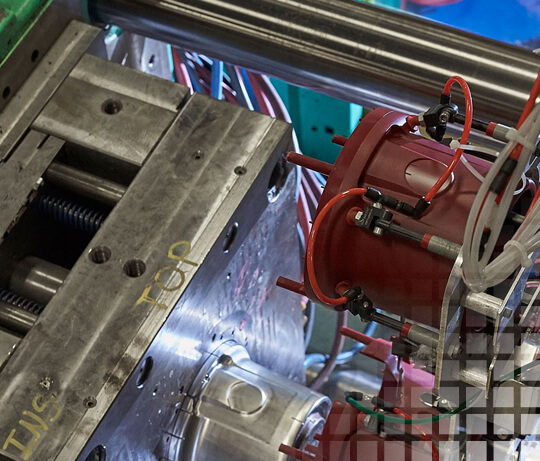

Custom Plastic Injection Molding

High-quality plastic injection molding services backed by 70+ presses, ISO 9001:2015 processes, and a team built for long-term OEM partnerships.

About Hansen Plastics

With over 50 years of experience, Hansen Plastics Corporation is a leader in custom plastic injection molding. Our commitment to quality and innovation has earned us recognition as a top supplier in the industry, including ISO 9001:2015 certification. With a press range designed to support a wide variety of part sizes and complexities, we help customers reduce risk, improve part consistency, and simplify supply planning. Hansen Plastics provides custom plastic injection molding for OEMs that need consistent parts, predictable lead times, and manufacturing support that scales. From prototype runs to high-volume production, our plastic injection molding team helps you move faster with repeatable processes, material guidance, and practical collaboration.

Plastic Injection Molding Services

Our plastic injection molding services cover multiple processes to match your part requirements, resin selection, and performance targets. Whether you need high-output horizontal molding, vertical and insert molding, multi-material molding, or decoupled molding for tighter process control, we focus on repeatability, quality checks, and practical manufacturability.

Horizontal Molding

Horizontal injection molding is a key service at Hansen Plastics, known for its versatility and efficiency in producing high-quality plastic components. In this process, the mold opens and closes in a horizontal direction, allowing for a wide variety of part shapes and sizes. This technique is ideal for creating parts with complex geometries while maintaining a fast cycle time and consistent quality. With our state-of-the-art machinery, we can meet the needs of various industries, ensuring precision, durability, and cost-effectiveness in every production run.

Horizontal molding is a strong fit for high-volume plastic injection molding where cycle time, repeatability, and throughput matter. We help customers optimize gate location, cooling, and part ejection to support stable production runs and consistent dimensions.

Vertical/Insert Molding

As employee owners, we are dedicated to finding the most efficient ways to help produce our high-quality products. Insert molding is the process of forming plastic pieces around other non-plastic pieces. Not only is this method extremely customizable, it is frequently used to eliminate the sub-assembly process, integrating molding and assembly into one complete molding operation. HPC has the capacity to utilize our vertical molding process to mold other components for your product, which otherwise would need to be assembled using expensive assembly equipment.

Insert molding is ideal when you need metal or threaded inserts, improved pull strength, or fewer assembly steps. Our custom plastic injection molding approach supports insert placement, part retention features, and repeatable overmolding for functional assemblies.

Multi-Material Molding

If you are ever searching for custom plastic molding, look no further than Hansen Plastics. At HPC, we are leading experts in the field of 2-shot and true multi-material molding thanks to our talented and diversely-skilled team members. Multi-material molding offers a 2-step process performed in a single machine, thus simplifying the production process and lowering the overall part cost. Additionally, 2-shot and multi-material molding allow the injection of two materials into the same mold, offering new design options such as different colors and textures while eliminating secondary operations, making injection molding more economical and efficient.

Our Engineering and Management staff at HPC is highly educated and experienced in the areas of plastic materials, process engineering, lean manufacturing, and tool design. Simply stated, HPC is capable of molding your most complex designs based on rock-solid expertise in tool design and manufacturing. Contact us if you have any questions about the multi-material molding process or any of our services.

Multi-material molding supports parts that need soft-touch grips, sealing surfaces, or combined rigidity and flexibility in one component. This process can reduce secondary assembly while improving fit and performance.

Decoupled Molding

In Decoupled Molding (SM) pressure sensors are strategically located inside the mold to read the molding pressure. When the pressure reaches a recognized value, the machine transfers to a set point. This allows HPC’s molding engineers to precisely control:

- Pressure

- Shrinkage

- Dimensions

We utilize scientific Decoupled Molding (SM) in a variety of products, using sophisticated RJG software. This software integrates into the molding machine’s electronics and Hansen Plastics’ ERP business management system. Our tool design engineers take the art of molding and turn it into a true science by “instrumenting” the mold through the use of pressure transducers, all linked into our molding and business enterprise operating software.

Decoupled Molding (SM) allows process capability to be achieved beyond traditional plastic injection molding techniques. It can provide excellent process repeatability by separating the molding processes into rational stages of fill, pack, and hold. Maintaining these three stages allows our molders to build a repeatable, robust process with minimal complexity.

Decoupled molding separates and controls key phases of the injection process to improve consistency across shots. It can be especially useful for tighter tolerance plastic injection molding and parts with more demanding cosmetic or functional requirements.

Why Choose Hansen Plastics for Custom Plastic Injection Molding?

Advanced Technology

Utilizing the latest in injection molding equipment and software

Expert Team

Highly skilled engineers and technicians with decades of experience

Quick Turnaround

Efficient processes to meet your deadlines

Exceptional Quality

Rigorous quality control measures ensure consistent, high-quality parts

Testimonials

“My company is in the water delivery business. My role in the company is a Senior Buyer. I have been doing business with HPC for 4 years, however, the company I represent has been doing business with HPC for over 30 years. During that time I have f... Read More

– Scott Olberding, Senior Buyer, Elkay

“My company is in the Automotive tool business. My role in the company is President. I have been doing business with HPC for 12 years. During that time I have found HPC to be Informative… Once expectations are understood, HPC is an excellent comm... Read More

– Eric Leicher, President, Motive Products

“Because of your support, we will be able to provide our guests with a safe place to sleep, food, clothing, coats, shoes, a hot shower, and laundry facilities.”... Read More

– Sarah J. Ponitz, Executive Director, Pads of Elgin

Industries We Serve with Custom Plastic Injection Molding

We provide custom injection molding services across multiple industries, with part requirements ranging from outdoor durability to precision tolerances and repeatable cosmetic finishes.

Appliances

We provide custom plastic injection molding solutions for the appliance industry.

Fluid Movement

Innovative plastic solutions for fluid movement and water treatment industries.

Transportation

Providing high-quality plastic components for the transportation industry.

Custom Plastic Injection Molding Capabilities

- Wide range of engineering-grade and commodity resins

- Production volumes from prototypes to high-volume runs

- In-house mold design and fabrication

- Value-added services like assembly and packaging

- Press tonnage support for a range of part sizes (28 to 500 tons)

- High-volume production support and repeatable process controls

- Design-for-manufacturability input to reduce risk before tooling

- Resin and material guidance for strength, heat, chemical exposure, and cosmetics

- Secondary operations as needed (trim, assembly, packaging, kitting)

- Inventory and supply programs to improve continuity of supply

If you have an existing part and want to improve cost or performance, we can review the design and identify opportunities for material or tooling improvements.

Quality You Can Trust

At Hansen Plastics, quality is built into every step of our custom plastic injection molding process:

- ISO 9001:2015 certified quality management system

- Advanced inspection equipment including CMM and vision systems

- 100% part inspection on critical components

- Material certifications and lot traceability

Quality is built into every stage of our plastic injection molding process, from material verification to in-process checks and documented procedures. Our ISO 9001:2015 certification supports consistent execution, repeatable outcomes, and continuous improvement.

Ready to Start Your Custom Plastic Injection Molding Project?

Contact us today to discuss your custom plastic injection molding needs!

FAQs on Plastic Injection Molding Services

Plastic injection molding is the process. Custom plastic injection molding means the part, tooling, material, and process settings are tailored to your requirements, tolerances, and production volumes.

Yes. We support runs from early production to high-volume programs using repeatable process controls and inspection methods to maintain consistency.

Yes. We support vertical and insert molding as well as multi-material molding for parts that need integrated features, improved pull strength, or fewer assembly steps.

Typically we review a part drawing or CAD file, resin requirements if known, expected annual volume, target tolerances, and any secondary operations such as assembly, packaging, or labeling.