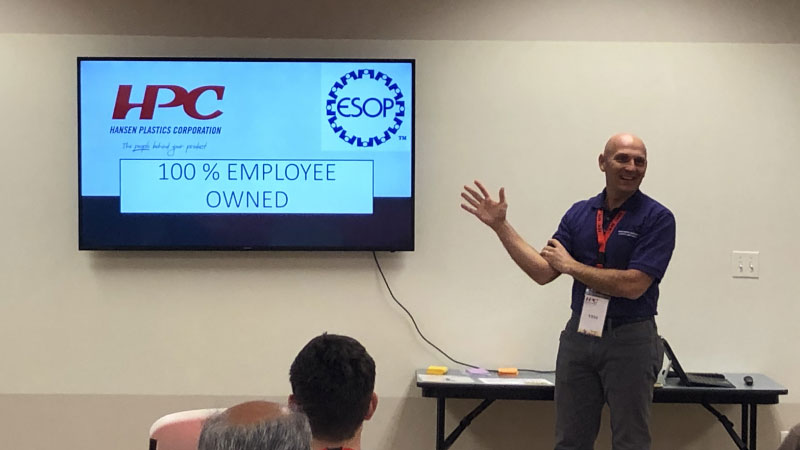

At Hansen Plastics, the people are the backbone and the secret sauce, dedicated to increasing success through continual improvement, creating consistently quality products, and building and maintaining long-term customer relationships. Driving this dedication is the fact that in 1998, Hansen Plastics Corporation chose to become 100% employee-owned. It was a bold move that paid off, shifting the mindset of each team-member at Hansen Plastics from that of just another employee, to that of an owner, with a true stake in the products and relationships that keep the company performing at its best. Adopting this mindset continues to help fuel the Employee-Owners of Hansen Plastics to continue to find ways to make their products, solutions, and experiences with customers the highest quality they can be.

An Exceptional Experience from the First Point-of-Contact

Introductions form an immediate lasting impression, for better or worse, which is why the Customer Service team at HPC goes out of their way to ensure that returning and new customers always feel well taken care of and welcome. “We try to treat our customers like they are the most important people that we get to interact with every day,” says Leslie Huerth, in Customer Service.

Creating a welcoming environment, answering inquiries with thorough information, and being willing to reach out to customers directly builds an immeasurable foundation of trust between the team at Hansen Plastics’ and their customers, an experience owned and enhanced by the Employee-Owners. This creates mutual respect on both sides of the experience. According to Ann Bottom, Customer Satisfaction Specialist, “I find it easier to talk to customers, and with that open line of communication — you’re able to get somewhere to resolve issues together, versus ‘They’re right, and it is what it is’.”

Achieving Quality and Consistency

Hansen Plastics operates 78 molding machines across two Value Streams — White and Blue — to produce a product for customers in a litany of industries, including Automotive, Medical, Electronics, Water Treatment, and Life Safety, just to name a few, which can become difficult to keep track of. “Every customer requires something totally different…there’s a ton of different terminologies used for the same exact thing or the same type of approval process, and it can be challenging to keep all that together,” notes Robert Sandeen, Blue Value Stream Leader.

But the responsibility associated with employee-ownership drives Hansen Plastics’ Employee-Owners to produce products at a higher level of quality and consistency to rise to the standards of each industry and customer they work with. “That’s why employee ownership is so powerful. Because nobody should think ‘I’m just doing whatever the owner wants’…” Robert adds.

Maintaining high standards of success for themselves, in conjunction with employing RJG’s Decoupled Molding SM and eDart® System to achieve higher levels of consistency while molding products, helps Hansen Plastics Employee-Owners raise the bar on the products that they mold and the relationships they maintain, creating an astonishing value-add to their customers.

To learn more about Hansen Plastics Corporation, their techniques, and their business philosophy, visit Hansenplastics.com.