One of the key reasons companies use injection molding for their parts is how precisely pieces can be manufactured — both in part complexity, and in aesthetics. Being able to establish how a part will look at the beginning of the design phase and retaining that vision through the manufacturing phase (barring any major necessary functional changes) is a level of control that injection molding provides where other processes fall short.

Still, to be fully functional, some parts require finishing after they have been molded. This includes parts that need to be joined or attached to other components to form the fully realized part. But joining these pieces together usually requires screws, bolts, adhesives, or other hardware that ultimately defaces the finished piece and takes away from that aesthetically pleasing finish that designers work so diligently to perfect. Fortunately, there is another method of joining plastic parts that is less invasive, equally durable, ultimately much faster and easier for companies. Enter ultrasonic welding. This is not to be confused with vibration welding which is very similar but the vibrations move up and down, instead of side to side.

What is Ultrasonic Welding?

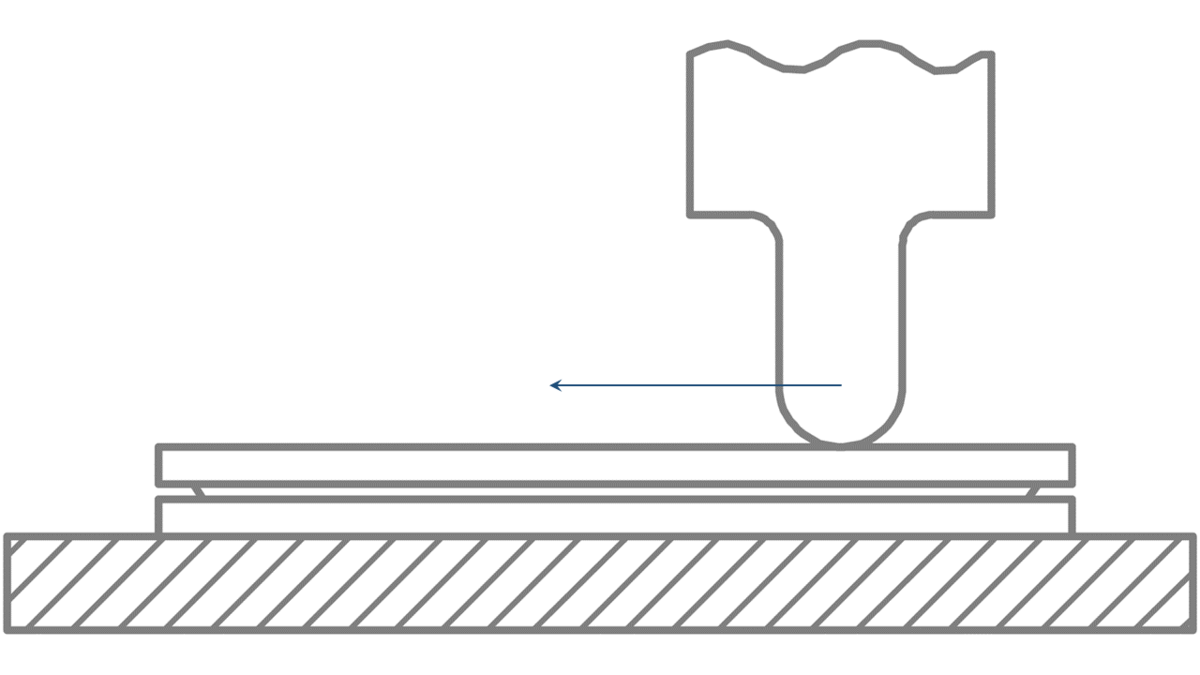

Ultrasonic welding is a process that joins two separate plastic pieces together to form one cohesive part. This is done using friction to generate heat, warming the plastics to a high enough temperature that they’re able to form a molecular bond. Specialized welding machines use a vibrating “horn” to apply high-frequency pressure via sound waves to the sides of the plastic pieces being welded together, which is what creates the friction and heat between the pieces to join them.

Once the pieces are heated and joined, they need to cool for a set “hold time” to complete the bonding process. As the melded plastic cools, pressure is maintained — this is what completes the “weld” between the pieces, and forms the finished molecular bond.

Why Use Ultrasonic Welding for Plastic Parts vs Traditional Assembly Methods?

Ultrasonic welding forms a clean, strong bond between plastic pieces. Because it only forms a bond using heat and pressure, with no outside additional materials or agents, the welded part is left uncontaminated from outside agents, preventing the introduction of undue duress, corrosion, or discoloration into the part. This is also ideal for joining different types of plastics that may not be able to be molded together, or for parts that needed to be molded in separate batches. This does not work for joining all material types, but those that are chemically compatible and have similar melt flow dynamics tend to weld together easily.

The ultrasonic welding process is also fully contained, meaning no additional assembly is required once the assembly process is finished. Because this process takes seconds to minutes per piece, rather than minutes to hours for physical assemblies, it ultimately saves time and money during the manufacturing process, as well.

Considerations with Ultrasonic Welding

The point of using ultrasonic welding to merge pieces is the long-lasting durability. To that end, this process is not ideal for parts that need to be disassembled to be checked or updated regularly. Companies will still want to be mindful of the materials being used in each piece as well, because as mentioned above, not every material can be welded together.

Overall, so long as companies understand the material and bond strength considerations, ultrasonic welding can be an ideal finishing solution to bond pieces into a single, functional part. However, sometimes, this decision can be unclear, and companies look for guidance on the best choice for how to mold and assemble their parts. Fortunately, partnering with a plastic injection molder like Hansen Plastics Corporation helps clear up any uncertainty about the best design, molding process, and finishing used on each part. HPC makes sure to work with their customers to ensure each finishing process employed is the best option for the parts being produced, taking the time to understand their customer’s business, their needs, and their ultimate goals with their manufactured parts. Hansen Plastics is dedicated to offering an injection molding experience that is open, honest, affordable, and quality for each customer they partner with.

The team at Hansen Plastics is dedicated to meeting their client’s level of expected quality and affordability — and exceeding their industry’s standards — by producing plastic injection parts with continuous innovation in the plastic injection molding process. If you are looking for a trusted partner with 50 years of experience as a quality plastic injection molder, reach out to HPC today, or visit HansenPlastics.com for a full view of Hansen Plastic’s capabilities.

Image Source: https://commons.wikimedia.org/wiki/File:Scan_ultrasonic_welding.png